Engineering, production and sale of semi-trailers

Engineering, production and sale of semi-trailers

WHY TO CHOOSE SPECPRICEP

We constantly introduce innovations and obtain patents on our equipment.

Our company has its own design-engineering department. Our employees are masters of what they do and true technical geniuses. Every year we create absolutely new products for the Russian market. The company provides 30 unique options for semi-trailers and different components, and some of these options were already granted a patent.

Many Russian manufacturers copy our technical solutions.

The desire of competitors to introduce products that are similar to the products of SPECPRICEP proves that we are effective and our equipment is in demand. Furthermore, a copy always remains just a copy.

Our semi-trailers are adapted for work in the most difficult conditions.

First of all, we manufacture semi-trailers for the Russian conditions, which means that they are adapted for the lack of good roads and low temperatures. They can carry out tasks in such conditions because in production we use high-strength imported steel that guarantee reliability and reduces the construction weight. We also use components that have gained recognition in the European market. Using such materials allows us to obtain the maximum strength and durability of the machines.

Our design and engineering department uses the modern software tool SolidWorks.

The software tool SolidWorks can help solve a great variety of problems and allows users to automate work at the design and engineering stage. Using this unique technology to create 3-D models, allows the company to develop and introduce innovative products to the market. SolidWorks is widely used, for example, by rocket and rocket engines manufacturers, which is the industry that requires preciseness and does not tolerate mistakes. We can only accept such reliable tools for design and engineering.

Our technological department uses the best German programs for highly precise metal cutting.

Well-prepared metal cutting guarantees not only the quality of semi-trailer components but also reasonable usage of materials and the time of processing, which as the result reduces the prices for our products. This is the reason why our technology specialists use the best up-to-date software to create precise cutting maps.

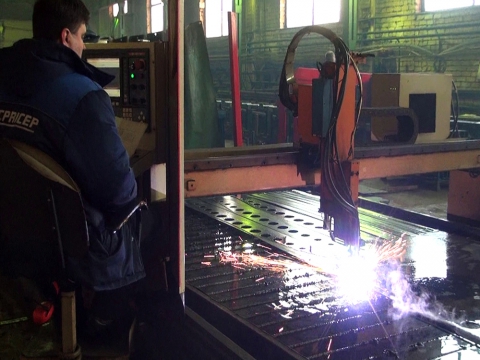

The tools for plasma-arc metal cutting that we use were developed specifically for SPECPRICEP.

Plasma-arc metal cutting is the most efficient way of thermal thick metal cutting, which is especially effective for solving problems that require quality and need to be done in short periods of time. This method is even more advantageous in terms of using high-tech equipment adapted for specific production purposes. One of the main specifications of the tool developed for SPECPRICEP is in its ability to reduce thermal metal loading and provide cutting high-strength Swedish steel without flash and dross.

Welding at our factory is carried out by using the best European tools Fronius and EWM.

We take very seriously everything that has to do with technical equipment of our factory, and every 5 years we change obsolete equipment for the modern one. When modernizing specific equipment such as different welding tools, we carry out multiple tests before we choose and start using the tools. The tools and equipment that we use today satisfy our strict demands in terms of weld joints—this allows us to automate the welding process and guarantee the maximum exactness of works.

Semi-trailer painting is carried out only after shot blasting.

Metal cleaning using the shot blasting method allows us to obtain the maximum cleanness of the surface before we put paint-and-lacquer coating, which guarantees the quality and durability of the paint. The processing of components in a shot blasting machine gives another good result—the packing of metal surfaces. This helps to make the surface more resistant to corrosion and deformations.

We extend the durability of semi-trailers using the aluminum and zinc alloy..

The protection of metal against corrosion for 20 years and more is achieved by application of aluminum and zinc. Aluminum is especially strong against high temperatures and dirty environments—it creates a layer that reduces the surface permeability. In its turn, zinc highly resists mechanical damages. The combinations of these two metals makes our semi-trailers almost invulnerable for different factors that can destroy the equipment over the course of long-term operation.

We implement strict technical control over the production processes.

The specialists of our technical control department know exactly how the high-quality product should look like and how to make it. Every stage of the production process is under their continuous monitoring, which allows them to prevent any mistakes or defects. In addition to the technical control department, every other employee of SPECPRICEP pays special attention to the quality of our products—this process is implemented according to the management quality system that is certified according to GOST R ISO 9001-2011.

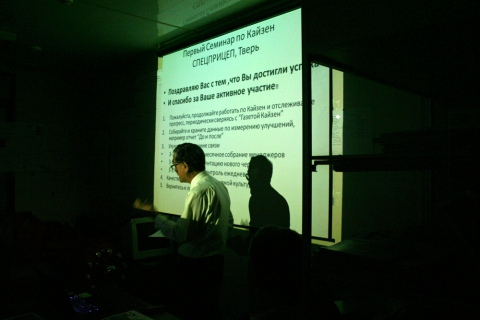

We always learn and we always develop our products. We get help from foreign specialists in terms of development as well.

We did not stop even after we had achieved great results. We are perfectionists. On a regular basis our specialists go through testing and additional instructions—from participating in international exhibitions and seminars to practical classes with visiting Russian and foreign experts. For example, our factory is visited by representatives of the best factories of Great Britain and Japan. Experience exchange allows our workers to plan the production process more effectively and rationally, which helps to reduce the production time.

Having partners like ours is a pride for any company.

The reliability of our semi-trailers has gained recognition of dozens of customers from different industries including such huge organizations as the Federal agency Spetsstroy Russia, OJSC Gazprom, OJSC AK Transneft, the group of companies Transstroi and SU-155, the diamond extracting companies group ALROSA, and US oil service companies. Our equipment was used in construction for the Olympic Games in Sochi. It is used on a permanent basis for mining and operation of oil and gas deposits as well as at nuclear stations and in many other important areas.

Each individual client works with a personal manager.

Our managers work with clients during the whole operation cycle of our products. At the preliminary stage, our managers determine the needs of each customer, compare them with the production capacities of our company and offer an optimal configuration for semi-trailers. Over the course of the production process, you can always ask our managers questions about the qualities of semi-trailers, request current photos and visit the factory in person—we support open communication. Upon receiving the equipment, we will always be happy to give consultations for our clients in terms of operation and technical support.

We teach our clients how to use our products correctly.

We created a special department that specializes in how to prolong the term of repair-less operation of semi-trailers and how to make the process of using our equipment as comfortable as possible for our clients. The department employees will explain to our customers all the specification for their equipment and provide them with detailed instructions on operation in real-life situations.